Momina Apparel is making denim garments more sustainable. We continue to invest in processes and business practices that are even better for the planet and for its people. That includes equipment and technologies that lower the amount of water and energy we put into a pair of jeans. And we continually invest in innovating products that help lead the industry in reducing harmful impacts of denim from agriculture to landfills. We know it’s working because we maintain Environmental Impact Measurement data, which we share with our clients.

FABRICS (We have developed a reliable supply chain and comprehensive measures to deliver more sustainable fabrics. Our Mill is certified with Global Organic Textile Standard (GOTS) for organic content in our fabric and Global Recycle Standard (GRS) for all the synthetic recycled fibers used in the form of Repreve, PIW, PCW etc in our fabrics. We are also using BCI cotton in our fabrics as well as regenerated fibers that are biodegradable such as Tencel, Viscose, Modal, etc to add comfort to the fabric without having any harmful effect on environment.)

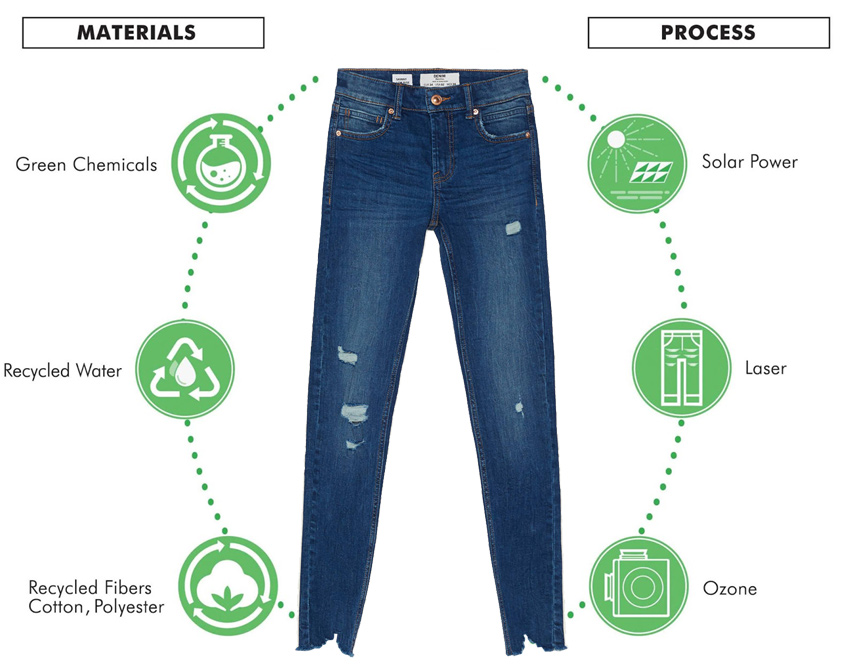

To reduce the use of hazardous chemicals in the supply chain, we have a dedicated Technical Representative for chemical management. We always purchase chemicals from approved chemical suppliers with all the compliance documents like PSD, CIL, SDS, COA and TDS. We can ensure we always use the chemicals and dyes that are in compliance with Restricted Substances List. We used chemicals from Rudolf – Germany and Archroma - Switzerland.

Throughout our mill, we are continuing to shrink our carbon and non-renewable footprint. We minimize the water needed for dyeing using new chemistries. We recover heat from processing water and steam, and from engine cooling. We are completing our retrofits of LED lighting, hyper efficient pumps, motors and processes.